Our Research Projects

I. Simple Interval Calculation (SIC)

Simple Interval Calculation (SIC) is a method of linear modeling

y = Xa + errors

that gives the result of prediction directly in the interval form. The

SIC also approach provides wide possibilities for the Object Status Classification,

i.e. leverage-type classification of relative importance of the calibration

and test sets samples with respect to a model.

Click the icon

to open a PowerPoint file (= 870 kB) "Simple Interval Calculation (SIC) - Theory and

Applications", presented at the

Second Winter School on Chemometrics (WSC-2),

Barnaul, Russia, 2003.

to open a PowerPoint file (= 870 kB) "Simple Interval Calculation (SIC) - Theory and

Applications", presented at the

Second Winter School on Chemometrics (WSC-2),

Barnaul, Russia, 2003. |

Click

here

to ask for the file by e-mail |

The SIC approach is based on the single assumption that all errors are

limited (sampling errors, measurement errors, modelling errors), which would

appear to be reasonable in many practical applications. For prediction

modelling, this leads to results that are in a convenient interval form. The

SIC approach assesses the uncertainty of predicted values in such a way that

each point of the resulting interval has equal 'possibility'. The

SIC-interval is in contrast to the traditional confidence interval

estimators, which are based upon theoretical error distributional model

assumptions, which rarely hold for practical data analysis of technological

and natural systems. No probabilistic measure is introduced on the error

domain, therefore one does not have to evaluate the likelihood of the values

within the resulting prediction interval.

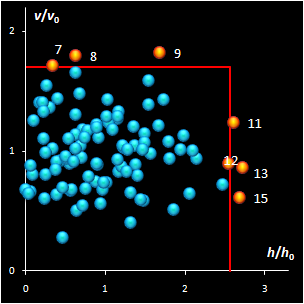

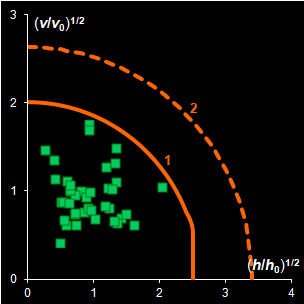

The finiteness of the error helps to construct the Region of Possible

Values (RPV) (Fig. I.1), a limited region in the parameter space that

includes all possible parameter values that satisfy the data set & model

under consideration.

Fig.I.1: Illustration of RPV in model parameter space.

The initial data set contains 24 objects but only 12

were necessary to form the RPV.

The SIC-approach does not use an(y) objective function (e.g. sum of

squares) for the parameter estimate search. In conventional regression

analysis these estimates are the values of unknown parameters, which agree

with the experimental data in the best way. In the SIC method any model

parameter value that does not contradict experimental data, i.e. lies inside

or on the border of RPV, is accepted as a feasible estimate.

The RPV concept provides wide possibilities for selection the samples from

calibration set that are of the most importance for model construction. This

is because the RPV is formed not by all objects from the calibration set,

but only by so-called boundary objects. Therefore, if we exclude all

objects from the calibration set except boundary ones, the RPV will not

change.

The position of a new objects (e.g. test set objects, or new X-data alone)

in relation to the RPV helps to understand the object

similarities/dissimilarities in comparison with those from the calibration

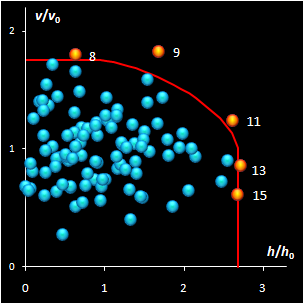

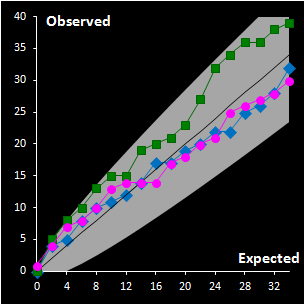

set. The object status map (see Fig. I.2), or so called the SIC

influence plot, can be constructed for any dimensionality of initial data

set [X, y] and any number of estimated model

parameters.

Fig. I.2: The example of Object Status map for real world data.

Samples Ñ1-Ñ11 ( )

are the calibration objects.

)

are the calibration objects.

Samples T1-T4 ( ) are

the test objects.

) are

the test objects.

Samples C2, C1, C6, and C11 are the boundary objects.

Sample T1 is an insider, sample T2 is an outsider

Sample T3 is an absolute outsider. Sample T4 is an outlier.

SIC returns an object status classification which divides the SIC-

residual vs. SIC - leverage plane into three categories: 'insiders'

(new objects very similar to the calibration set) and 'outsiders'

(all other objects in the rest of this plane. It is possible to establish a

further distinction between 'absolute outsiders' and more extreme 'outliers'.

Description of the SIC-method and the Object Status Classification

approach is published in --

O. Ye. Rodionova, K. H. Esbensen, and A.L. Pomerantsev,

"Application of SIC (Simple Interval Calculation) for object

status classification and outlier detection - comparison with PLS/PCR",

J. Chemometrics, 18 , 402-413 ( 2004)

DOI:10.1002/cem.885 |

Click

here

to ask for the file by e-mail |

No doubt that multivariate problems where data matrix is rank-

deficient are of great practical interest. To apply SIC-method to such

kind of problems we join it with traditional projection methods (e.g.,

principal component analysis or partial least squares).

We consider that the criteria of quality of interval prediction used

in SIC-procedure allow to look at the old problems of multivariate data

analysis from a new point of view. These problems are optimum number of

PCs, outlier detection, missing data, and insignificant observations. The roots of the method are in the old ideas of

Kantorovich to apply the linear programming to the data analysis. The

calculation aspects of SIC-method are rather simple since they founded

on the well-designed Simplex algorithm.

Now the SIC method is implemented in MATLAB script-language. The

software is presented

here.

An examples of the SIC-method are published in --

A.L. Pomerantsev, O.Ye. Rodionova, "Hard and soft

methods for prediction of antioxidants' activity based on the DSC

measurements", Chemom. Intell. Lab.Syst.,

79 (1-2), 73-83

(2005)

DOI:110.1016/j.chemolab.2005.04.004 |

Click

here

to ask for the file by e-mail |

A.L. Pomerantsev, O.Ye. Rodionova, A. Höskuldsson,

"Process control and optimization with simple interval calculation method",

Chemom. Intell. Lab.Syst., 81 (2), 165-179 (2006)

DOI:10.1016/j.chemolab.2005.12.005 |

Click

here

to ask for the file by e-mail |

| A.L. Pomerantsev and O.Ye. Rodionova, "Prediction

of antioxidants activity using DSC measurements. A feasibility study",

In Aging of Polymers, Polymer Blends and Polymer Composites, 2,

Nova science Publishers, NY, 2002, pp. 19-29 (ISBN 1-59033-256-3). |

Click

here

to ask for the file by e-mail |

| O.Ye. Rodionova, A.L. Pomerantsev, "Principles of

Simple Interval Calculations" In: Progress In Chemometrics

Research, Ed.: A.L. Pomerantsev, 43-64, NovaScience Publishers,

NY, 2005, (ISBN: 1-59454-257-0) |

Click

here

to ask for the file by e-mail |

| A.L. Pomerantsev and O.Ye. Rodionova,

"Multivariate Statistical Process Control and Optimization",

Ibid, 209-227 |

Click

here

to ask for the file by e-mail |

|

|

|

II. Nonlinear Regression

(NLR)

The main purpose of non-linear regression is to fit

data with a non-linear model, to predict response for predictor values that are

far from the observed ones, to estimate the uncertainties in prediction.

Click the icon

to open a PowerPoint file (=1290 kB) "“Introduction to

non-linear regression analysis" (in Russian), presented at

the

Second Winter School on Chemometrics (WSC-2),

Barnaul, Russia, 2003.

to open a PowerPoint file (=1290 kB) "“Introduction to

non-linear regression analysis" (in Russian), presented at

the

Second Winter School on Chemometrics (WSC-2),

Barnaul, Russia, 2003. |

Click

here

to ask for the file by e-mail |

These ideas were implemented in the software

FITTER, a new

Excel Add-In.

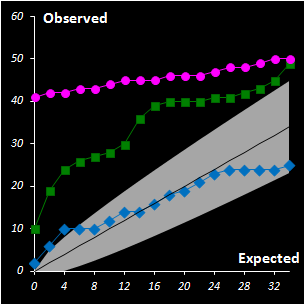

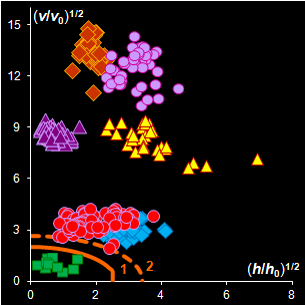

Consider example of rubber aging prediction. Data of

accelerated aging tests, performed at temperatures: T=140C, 125C and 110C, are

presented in Fig II.1.

Fig II.1: Experimental data (left Y- and bottom X-axes)

and predicted kinetics (right Y- and top X-axes)

The response ELB is the 'Elongation at break' property that is

measured in accordance with ASTM D412-87. The data are fitted with the first

order kinetics, which rate constant k depends on temperature by the

Arrhenius law:

ELB=ELB1+(ELB0-ELB1)*exp(-k*t),

k=k0*exp[-E/(RT)],

where ELB0, ELB1, k0,

and E are unknown parameters. Prediction is performed at normal

temperature 20oC and the left (bottom) limits of confidence intervals are

obtained. This example is presented in:

E.V. Bystritskaya, O.Ye. Rodionova, and A.L.

Pomerantsev "Evolutionary Design of Experiment for Accelerated

Aging Tests", Polymer Testing, 19, 221-229, (1999)

DOI:10.1016/S0142-9418(98)00077-4 |

Click

here

to ask for the file by e-mail |

O. Y. Rodionova, A. L. Pomerantsev "Prediction of

Rubber Stability by Accelerated Aging Test Modeling", J Appl

Polym Sci, 95 (5) 1275-1284, (2005)

DOI:10.1002/app.21347 |

Click

here

to ask for the file by e-mail |

|

|

|

III. Statistics

Theoretical statistics is an area of our interests.

Making the forecast, it is essential to

find not only the point prediction value, but also to characterize the

uncertainty, which firstly depends on the extrapolation distance. Certainly, the

most convenient way is to present the result of prediction as a confidence

interval.

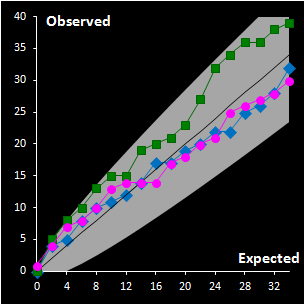

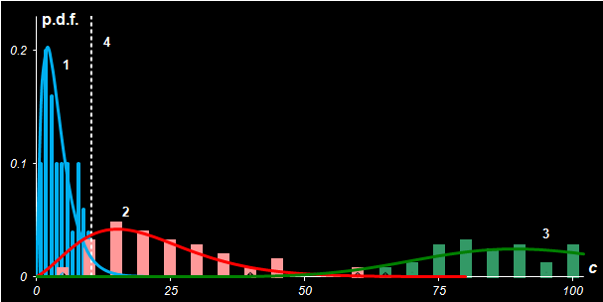

Fig III.1: Upper bounds of confidence intervals versus confidence

probability P for various methods: F, A, M, B,

L, S, and "exact" values T

We suggest a new method of confidence estimation for

NLR, where, unlike bootstrap, we simulate parameter estimates, not initial data.

The details are presented in

A.L. Pomerantsev "Confidence Intervals for Non-linear

Regression Extrapolation", Chemom. Intell. Lab. Syst, 49,

41-48, (1999)

DOI:10.1016/S0169-7439(99)00026-X |

Click

here

to ask for the file by e-mail |

The difference in the confidence intervals constructed

for a nonlinear model by various methods can be very great (see Fig. III.1), but in some cases

this difference could be negligible from the "engineering" point of

view. To explain this, we suggest a new coefficient of nonlinearity, which is

used for the decision-making about the method that can be utilized for a given

task. It is calculated by the Monte Carlo procedure and accounts for the model

structure as well as the experimental design features. More information about

the coefficient of nonlinearity is published in

These ideas were implemented in the software

FITTER, a new Excel Add-In.

|

|

|

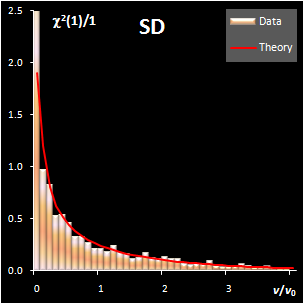

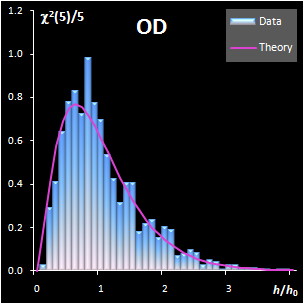

IV. SIMCA

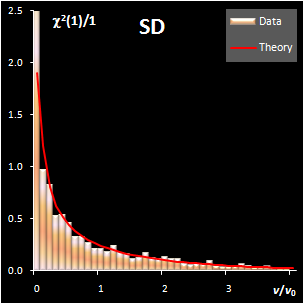

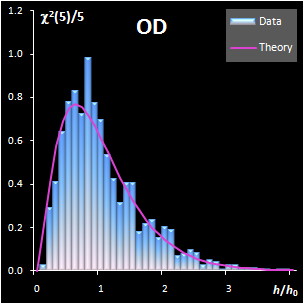

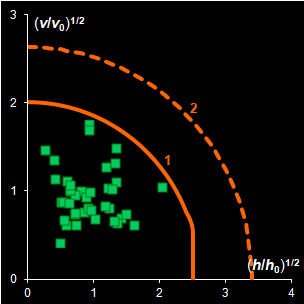

In the projection methods (PCA, PLS) two distance

measures are of importance. They are the score distance (SD, a.k.a. leverage, h) and the orthogonal distance (OD, a.k.a. the

residual

variance, v). This research shows that both distance measures can be

modeled by the chi-squared distribution (Fig IV.1). Each model

includes a scaling factor that can be described by an explicit equation.

Moreover, the models depend on an unknown number of degrees of freedom (DoF),

which have to be estimated using a training data set. Such modeling is further

applied to classification within the SIMCA framework, and various acceptance

areas are built for a given significance level. .

|

|

|

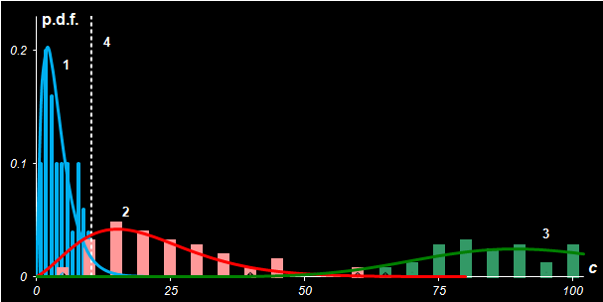

Fig. IV.1: Example of the SD and OD distributions.

I=1440, A=6, Nh=5,

Nv=1 |

The SD and OD distributions are similar. Each of them

depends on a single unknown parameter, Nh and Nv

that are the effective DOFs. In our opinion, the estimation of DoF is a key

challenge in the projection modeling. In case of SD, DoF should be close to the

number of PCs used, i.e., Nh ≈A; and, in case of

OD, DoF is undoubtedly linked to the unknown rank of the data matrix, K=rank(X),

e.g. Nv ≈K–A. However, such evaluations

are valid only under an assumption that either data, or scores, are normally

distributed, which is always a dubious conjecture. Therefore, we believe that a

data-driven estimator of DoF, rather than a theory-driven one should be used.

The conventional method of moments is sensitive to outliers, therefore other

techniques have to be applied. The first approach is the robust estimation via

IQR estimator. The second way is the statistical simulation technique, such as

bootstrap and jackknife.

|

|

|

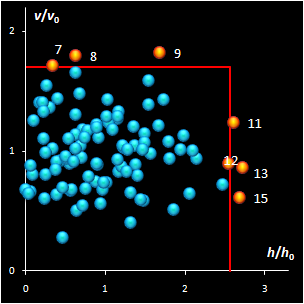

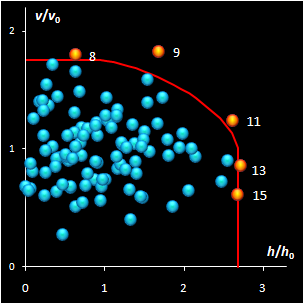

Fig. IV.2: SIMCA classification with the conventional

(left) and new (right) acceptance areas |

It is clear that any classification problem within the

projection approach should be solved with respect to a given significance level,

α,

i.e. the type I error. At the same time, the SD-OD, a.k.a. influence plot

is a valuable exploratory tool for the identification of the influential,

typical, extreme, and other interesting objects in data. In this plot different

acceptance areas can be constructed. They are the regions where a given share,

1–α, of the class members belongs to. Two of such areas are presented in

Fig. IV.2.

All of them are valid, i.e. they comply with the type

I error requirement, but not all of them are practical. Left panel shows the

conventional rectangle area, and the right panel represents the acceptance area,

which follows from the modified Wilson-Hilferty approximation of the chi-squared

distribution.

Click the icon

to open a PowerPoint file (=3.3 MB) "Critical levels in

projection techniques ", presented at the

Six Winter Symposium on Chemometrics (WSC-6),

Kazan, Russia, 2008.

to open a PowerPoint file (=3.3 MB) "Critical levels in

projection techniques ", presented at the

Six Winter Symposium on Chemometrics (WSC-6),

Kazan, Russia, 2008. |

Click

here

to ask for the file by e-mail |

A. Pomerantsev "Acceptance areas for multivariate

classification derived by projection methods", J. Chemometrics,

22, 601-609 (2008)

DOI: 10.1002/cem.1147 |

Click

here

to ask for the file by e-mail |

|

|

|

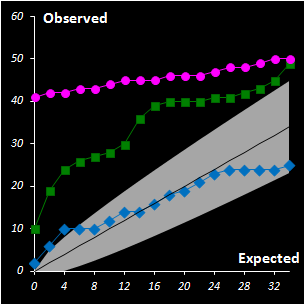

Fig. IV.3 : Extreme plots:

observed number of extreme objects vs. the expected number. Grey area

represents the 0.95 tolerance limits. |

For the construction of a reliable decision area in

the SIMCA method, it is necessary to analyze calibration data revealing the

objects of special types such as extremes and outliers. For this purpose a

thorough statistical analysis of the scores and orthogonal distances is

necessary. The distance values should be considered as any data acquired in the

experiment, and their distributions are estimated by a data driven method, such

as a method of moments or similar. The scaled chi-squared distribution seems to

be the first candidate among the others in such an assessment. This provides the

possibility of constructing a two-level decision area, with the extreme and

outlier thresholds, both in case of regular dataset and in the presence of

outliers. We suggest application of classical PCA with further use of enhanced

robust estimators both for the scaling factor and for the number of degrees of

freedom. A special diagnostic tool called Extreme plot is proposed for the

analyses of calibration objects (see Fig IV.3). Extreme objects play an important role in data

analysis. These objects are a mandatory attribute of any data set. The advocated

Dual Data Driven PCA/SIMCA (DD-SIMCA) approach has demonstrated a proper

performance in the analysis of simulated and real world data for both regular

and contaminated cases. DD-SIMCA has also been compared to ROBPCA, which is a

fully robust method

Click the icon

to open a PowerPoint file (=3.2 MB) "Dual data driven SIMCA as a

one-class classifier", presented at the Nineth Winter Symposium on Chemometrics

(WSC-9),

Tomsk, Russia, 2014.

to open a PowerPoint file (=3.2 MB) "Dual data driven SIMCA as a

one-class classifier", presented at the Nineth Winter Symposium on Chemometrics

(WSC-9),

Tomsk, Russia, 2014. |

Click

here

to ask for the file by e-mail |

A.L. Pomerantsev, O.Ye. Rodionova, "Concept and role of

extreme objects in PCA/SIMCA", J. Chemometrics,

28,

429–438 (2014)

DOI: 10.1002/cem.2506

|

Click

here

to ask for the file by e-mail |

Y.V. Zontov, O.Ye. Rodionova, S.V.

Kucheryavskiy, A.L. Pomerantsev, "DD-SIMCA – A MATLAB GUI tool

for data driven SIMCA approach", Chemom. Intell. Lab. Syst.

167, 23-28 (2017)

DOI:

10.1016/j.chemolab.2017.05.010 |

Click

here

to ask for the file by e-mail |

| Implementation of the Data-Driven SIMCA

method for MATLAB can

be downloaded from |

GitHub |

A novel method for theoretical calculation of the

type II (β) error in soft independent modeling by class analogy (SIMCA) is

proposed. It can be used to compare tentatively predicted and empirically

observed results of classification. Such an approach can better characterize

model quality, and thus improve its validation.

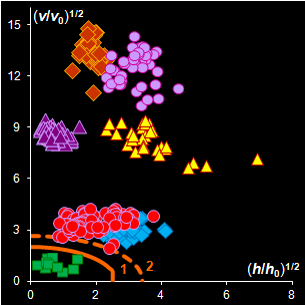

Fig IV.4: Fisher's Iris. Probability density distributions of

statistics c and c' in case

Versicolor (1) is the target class, while Virginica (2)

and Setosa (3) are the alternative classes.

Line 4 represents the critical cut-off value.

None of classification models are complete

without validation of the model quality, which is primarily associated

with the expected errors of misclassification. The type I error, α, is

the rate of false rejections (false alarm), i.e. the share of objects

from the target class that are misclassified as aliens. The type II

error β is the rate of false acceptances (miss), i.e. the share of

alien objects that are misclassified as the members of the target class.

When alternative classes are presented, the β-error can be calculated

for a given α-error as shown in Fig. IV.4. The α-error is equal to the

area under curve 1 to the right of line 4. The β-error is equal to the

area under curve 2 to the left of line 4. Moving critical level 4 we can

change the risks of wrong rejection (α) and wrong acceptance (β)

decisions.

A.L. Pomerantsev, O.Ye.

Rodionova, "On the type II error in SIMCA method", J.

Chemometrics, 28, 518-522 (2014)

DOI:

10.1002/cem.2610 |

Click

here

to ask for the file by e-mail |

|

|

|

Fig. IV.5 : Amlodipine, producer A4 is used as the

target class. PCA model with two PCs.

Acceptance areas: regular at α= 0.01 (1);

extended at β = 0.005 (2). Left panel:

training set; right panel: test set. |

In counterfeit combating it is equally important to

recognize fakes and to avoid misclassification of genuine samples. This study

presents a general approach to the problem using a newly-developed method called

Data Driven Soft Independent Modeling of Class Analogy. In classification

modeling the possibility to collect representative data both for training and

validation is of great importance. In case no fakes are available, it is

proposed to compose the test set using the legitimate drug's analogues

manufactured by various producers. These analogues should have the identical API

and similar composition of excipients. The approach shows satisfactory results

both in revealing counterfeits and in accounting for the future variability of

the target class drugs. The presented in Fig. IV.5 a case study

demonstrates that theoretically predicted misclassification errors can be

successfully employed for the science-based risk assessment in drug

identification.

O.Ye. Rodionova, K.S. Balyklova,

A.V. Titova, A.L. Pomerantsev "Quantitative risk assessment in

classification of drugs with identical API content", J. Pharm.

Biomed. Anal. 98, 186-192 (2014)

DOI:

10.1016/j.jpba.2014.05.033 |

Click

here

to ask for the file by e-mail |

|

|

|

V. Successive

Bayesian Estimation

The successive Bayesian estimation (SBE) of regression

parameters is an effective technique applied in nonlinear regression analysis.

The main concept of SBE is to split the whole data set into several parts.

Afterwards, estimation of parameters is performed successively - fraction by

fraction - with Maximum Likelihood Method. It is important, that results

obtained on the previous step are used as a priori values (in the Bayesian form)

for the next part. During this procedure, the sequence of the parameter

estimates is produced and its last term is the ultimate estimate. Description of

SBE is published in

| G.A. Maksimova, A.L. Pomerantsev, "Successive Bayesian

Estimation of Regression Parameters", Zavod. Lab., 61,

432-435, (1995) |

|

It was shown that this technique is correct and it

gives the same values of estimates for linear regression as the traditional

OLS approach. Moreover, in that case, the result does not depend on the

order of the series. In non-linear regression case, the situation becomes

more difficult but we can pose that all these properties are asymptotically

the same.

Click the icon

to open a PowerPoint file (=1890 kB) "Successive Bayesian estimation for linear and

non-linear modeling", presented at the Second Winter School on

Chemometrics (WSC-2),

Barnaul, Russia, 2003 )

to open a PowerPoint file (=1890 kB) "Successive Bayesian estimation for linear and

non-linear modeling", presented at the Second Winter School on

Chemometrics (WSC-2),

Barnaul, Russia, 2003 ) |

Click

here

to ask for the file by e-mail |

This method is

used for obtaining kinetic information from spectral data without any pure

component spectra (Fig. V.1, left). With the help of real-world example, this approach is

compared with known methods of kinetic modeling (Fig V.1, right).

|

|

|

Fig. V.1: Successive estimates of kinetic

parameters (left panel) and

ultimate estimates with

various methods presented by the 0.95 confidence ellipses (right

panel) |

This example is

presented in

A.L. Pomerantsev "Successive Bayesian estimation

of reaction rate constants from spectral data", Chemom. Intell. Lab. Syst,

66 (2), 127-139 (2003)

DOI:10.1016/S0169-7439(03)00028-5 |

Click

here

to ask for the file by e-mail |

O.Ye Rodionova, A.L Pomerantsev "On One Method of

Parameter Estimation in Chemical Kinetics Using Spectra with Unknown

Spectral Components", Kinetics and Catalysis, 45

(4): 455-466, (2004)

DOI: 10.1023/B:KICA.0000038071.51067.d5 |

Click

here

to ask for the file by e-mail |

|

|

|

VI. Fitter Add-In

FITTER is an Add-In procedure for Excel. If you are under Excel you can

open FITTER as any add-in file using Tools/Add-Ins menu command. It

will add the new menu item Fitter into Tools menu. Clicking it, the main

Fitter dialog for starting FITTER is activated.

Fig. VI.1: Main Fitter dialog

FITTER is a powerful instrument of statistical analysis. Using it you may

solve multivariate nonlinear regression problems. Much of the power of

FITTER comes from its ability to estimate parameter values of complicated

user-defined functions that may be entered in ordinary algebraic notation as

a set of explicit, implicit and ordinary differential equations. FITTER uses

the unique procedure for analytic calculation of derivatives and special

optimization algorithm which provides the high accuracy even for

significantly nonlinear models. All complicated calculations are performed

in the special DLL library created using C++ compiler, which provides high

speed processing. FITTER allows to include prior knowledge about parameters

and accuracy of measurement in addition to experimental data. Using Bayesian

estimation, you can process both unlimited arrays of single-response data,

and data referring to different responses.

Click the icon

to open a PowerPoint file (=1290 kB) "Non-linear Regression Analysis with Fitter

Software Application", presented at the First Winter School on

Chemometrics (WSC-1),

Kostroma,

Russia, 2002.

to open a PowerPoint file (=1290 kB) "Non-linear Regression Analysis with Fitter

Software Application", presented at the First Winter School on

Chemometrics (WSC-1),

Kostroma,

Russia, 2002. |

Click

here

to ask for the file by e-mail |

With the help of FITTER you can obtain a lot of additional statistical

information concerning the input data and the quality of fitting. Parameter

estimates, variances, covariance matrix, correlation matrix and F-matrix;

the starting and final values of the sum of squares and objective function,

error variance, and spread in eigenvalues of the Hessian matrix; error

variance for each observation point calculated by fit and by population.

Moreover, there are hypotheses testing for: Student's test for outliers,

test of series for residual correlation, Bartlett's test for

homoscedastisity, Fisher's test for goodness of fit. Also, you can calculate

confidence intervals for each observation point by linearization method or

with the help of modified bootstrap technique. Detailed description of

Fitter application is presented in

FITTER takes all information from open Excel workbook. Information should

be placed directly on a worksheets (Data and Parameters) or written in a

text box (Model). All results are also output as tables on the worksheets.

In purpose to explain what information you want to use, you need to register

it with the help of FITTER wizards. There are DATA, MODEL and BAYES

registration wizards. While working with different FITTER wizards you only

register the required information, change options and look through process

of registration. You may change data only on the worksheets but not inside

the wizards. Since your information (Data, Model, ...) has been registered

it is kept in memory till you replace it by another registration.

An example of Fitter application to the diffusion problems solution is

published in

A. L. Pomerantsev "Phenomenological modeling of

anomalous diffusion in polymers", J Appl Polym Sci, 96(4)

1102 - 1114, (2005)

DOI:10.1002/app.21540 |

Click

here

to ask for the file by e-mail |

Estimation of the parameters of the Arrhenius equation often leads to

multicollinearity, or, in other words, a degenerate set of equations in the

least-squares procedure. This circumstance makes it difficult to estimate

the unknown parameters. Simple expedients for model modification are

considered that reduce multicollinearity.

O. E. Rodionova, A. L. Pomerantsev "Estimating the

Parameters of the Arrhenius Equation", Kinetics and Catalysis,

46, 305–308, (2005).

DOI: 10.1007/s10975-005-0077-9 |

Click

here

to ask for the file by e-mail |

Click here to

know more about Fitter software.

|

|

|

VII. Counterfeit Drug

Detection

The problem of counterfeit drugs is important all

over the world. For the first time the World Health Organization (WHO)

obtained information about forgeries in 1982. At that time counterfeit drugs

were mainly found in the developing countries. The definition for “counterfeit

drug” by WHO is as follows: “A counterfeit medicine is one which is

deliberately and fraudulently mislabeled with respect to identity and/or

source. Counterfeiting can apply to both branded and generic products and

counterfeit products may include products with the correct ingredients or

with the wrong ingredients, without active ingredients, with insufficient

active ingredient or with fake packaging”

Nowadays, there are “high quality” counterfeit

drugs that are very difficult to detect. It is worth mentioning that fake

drugs include dietary supplements too. In such medicine non-declared

substances such as hormones, ephedrine, etc., may be found. According to WHO

information the spread of counterfeit drugs in different countries are as

follows: 70% of turnover is in developing countries and 30% is in

market-economy countries. The distribution of fake drugs with respect to

different therapeutic groups is as follows: (1) antimicrobial drugs 28%; (2)

hormone-containing drugs 22% (including 10% of steroids); (3) antihistamine

medicines 17%; (4) vasodilators 7%; (5) drugs used for treatment of sexual

disorders 5%; (6) anticonvulsants 2%; (7) others 19%. Visual control,

disintegration tests or simple color reaction tests reveal only very rough

forgeries. More complicated chemical methods are also used but all

these methods try to prove or disprove the content and concentration of an

active ingredient. But the main goal is to discriminate genuine and

counterfeit drug, even in cases where the counterfeit drug contains the

sufficient concentration of active ingredient and as a result to answer the

question: “Does given drug correspond to the original as it is marked on

the package?”

Express-methods for detection of counterfeit drugs

are of vital necessity. In many cases dosage forms contain not only active

substances but also excipients. The exact content of excipients could differ

for the genuine and fake drugs. It is proposed to apply near infra-red (NIR)

spectroscopy that could be used both for identification of

pharmaceutical substances and dosage forms independently of contents of an

active ingredient. NIR also could give information about the excipients in a

pharmaceutical preparation and thereby be able to detect counterfeit drugs

even with proper active substance. A feasibility study has been published in

O.Ye. Rodionova, L.P. Houmøller, A.L. Pomerantsev, P.

Geladi, J. Burger, V.L. Dorofeyev, A.P. Arzamastsev "NIR

spectrometry for counterfeit drug detection", Anal. Chim. Acta,

549, 151-158 (2005)

DOI:10.1016/j.aca.2005.06.018 |

Click

here

to ask for the file by e-mail |

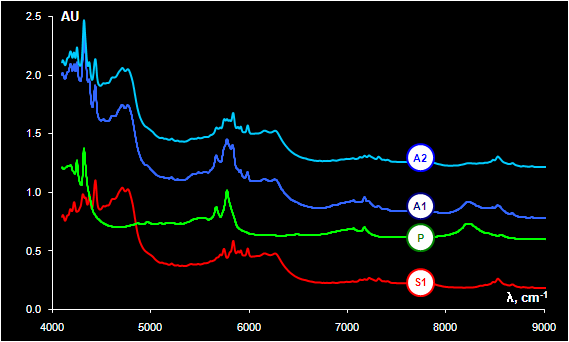

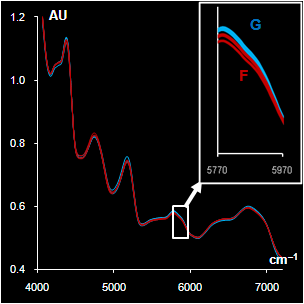

Two grades of tablets (antispasmodic drug,

uncoated tablets, 40 mg) are investigated. Ten genuine tablets, subset N1,

and 10 forgeries, subset N2 were measured using the InAs detector. After

that one tablet from set N1 was cut in half and a spectrum of the interior

of a cut tablet was measured; this was named N1Cut. The same procedure was

done for one tablet from set N2. As a result, in total 22 spectra were

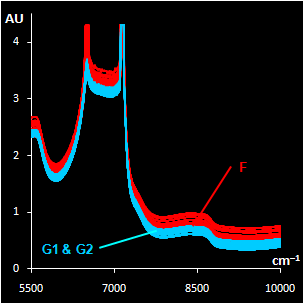

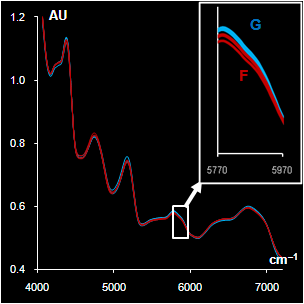

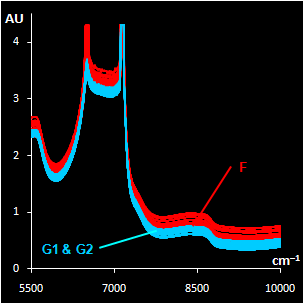

obtained. These spectra were pre-treated by MSC and are shown in Fig.

VII.1.

Fig VII.1: MSC pre-treated spectra . Blue lines (N1) are 11 genuine tablets

spectra

and red lines (N2) are 11 counterfeit tablets spectra.

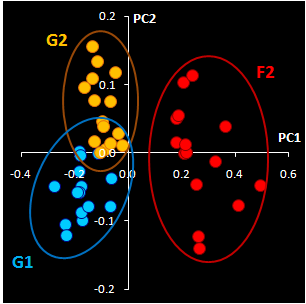

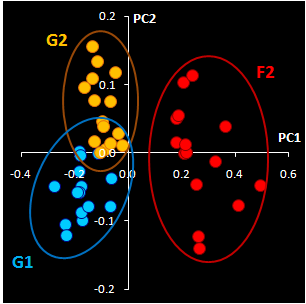

The data are subjected to a principal component

analysis. Taking into account two principal components (PCs) we come to the

following results (Fig. VII.2, left). Two manifest clusters in the PC1–PC2

plane are seen. Thus, the subsets N1 and N2 may easily be discriminated. The

object variance in subset N2 (counterfeit drug) is significantly greater

than the variance between objects in subset N1 (genuine tablets). This may

be explained by better manufacturing control for genuine tablets. Spectra

for the cut tablets are similar to the spectra of the whole tablets (compare open

dots).

|

|

|

Fig. VII.2: PCA scores plot (left panel) and SIMCA

plot (right

panel). Blue dots represent genuine tablets (N1)

and red squares represent counterfeit tablets (N2). Open dots

and squares show cut tablets. |

SIMCA method is applied to discriminate class N1

(genuine tablets) from any other counterfeit tablets .The “membership

plot” that presents the distance to model si

versus leverage hi is shown in Fig. 10, right panel.

The limits are shown as white lines: horizontal for the distance to model

and vertical for the leverage. It may be easily seen that the N1Cut object has a

low leverage, but its distance to the model is greater than the limit

though it lies not far from the model. Samples from set N2 are very far from

the model and undoubtedly can be classified as non-members of this

class.

In general, there is one class of genuine drug

samples and there may be plenty of forgeries of different degrees of

similarity. Due to the production quality demands in the large

pharmaceutical plants, the differences between the genuine items are rather

small. Nevertheless, we consider this investigation as a feasibility study

that yields promising results. For more trustworthy modeling it is necessary

to collect a representative set of genuine samples of the drug produced at

different times, with different shelf life, etc. On the other hand, the

diversity inside the counterfeit samples is essentially large. Sometimes the

difference between the genuine and counterfeit drugs could be seen visually

in the NIR spectra, but in other situations the answer is not so evident. To

claim that a sample is a forgery, it is not necessary to compare the

concentrations of active ingredients. All that is needed is to check whether

a given sample is identical to the genuine drug or not. The above analysis

shows that the NIR approach together with PCA has the good prospects and may

efficiently substitute wet chemistry.

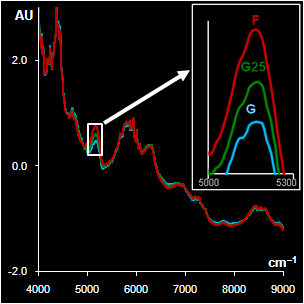

This a common opinion that the NIR spectroscopy is

a low sensitive method. However, being combined with a proper chemometric

analysis, this method demonstrates excellent results, which often are even

better (or compatible) than conventional "wet chemistry" approach. This study confirms this claim. The research is based on the case study of injection of Dexamethasone, which is a glucocorticosteroid remedy. The manufacturer

detected a batch of forgery medicine in the pharmaceutical market by

revealing the lack of several printing marks, which are hidden in the

package for security reasons. At the same time the standard pharmacopoeia

tests (GC-MS) held at the manufacturer facility did not confirm the counterfeiting

since the quality and quantity of the active substance was within the

standards. Later the suspicious drug (labeled F2) and genuine samples

(labeled G1 and G2) with identical

batch numbers (G2 and F2) were subjected to the NIR based analysis.

|

|

|

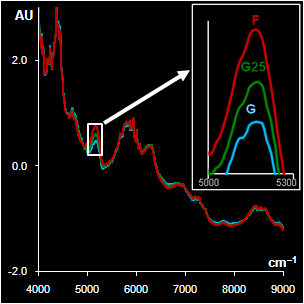

Fig. VII.3: Raw NIR spectra (left panel).

30 genuine samples G1 & G2 (blue) and 15 fakes F2 (red).

PCA

plot (right

panel). Blue and yellow dots represent G1 & G2, red ones stand for F2. |

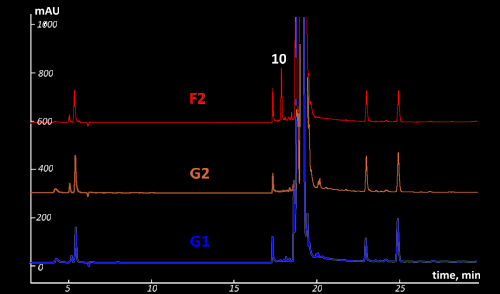

NIR spectra (Fig VII.3, left) were

obtained through the closed ampoules. PCA (Fig VII.3, right)

confirmed that genuine series G1 and G2 are very similar, but

suspicious sample F2 differs.

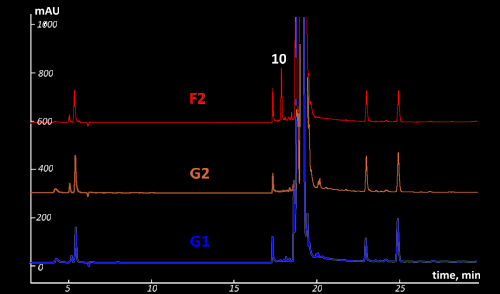

To compare the chemometrics based solution with

the conventional analytical methods the ampoules were opened and the drug

was subjected to the GC-MS, HPLC-DAD-MS, and CE-UV techniques. HPLC-DAD

chromatograms of the suspicious F2 and the genuine (G2 and G1) samples are shown

in Fig. VII.4.

Fig VII.4: Comparison of the HPLC-DAD chromatograms of the fake (F2) and

original (G2 and G1) samples. UV detection at 254 nm.

Mind peak (10) for suspicious sample F2. This peak

is absented for genuine samples G1 & G2

The results of the NIR tests have been completely

confirmed by the intensive chemical studies. Samples from batches G1 and G2

similar in their impurity composition but differ in the quantity of the

impurities. Difference in impurity composition reflects in NIR spectra and

helps easily to disclosure the counterfeited samples.

Click the icon

to open a PowerPoint presentation (=1.1 MB) "Another proof

that chemometrics is usable: NIR confirmed by HPLC-DAD-MS and CE-UV ", presented at

the Seventh Winter Symposium on

Chemometrics (WSC-7),

St Petersburg, Russia, 2010 )

to open a PowerPoint presentation (=1.1 MB) "Another proof

that chemometrics is usable: NIR confirmed by HPLC-DAD-MS and CE-UV ", presented at

the Seventh Winter Symposium on

Chemometrics (WSC-7),

St Petersburg, Russia, 2010 ) |

Click

here

to ask for the file by e-mail |

O.Ye. Rodionova, A.L. Pomerantsev, L. Houmuller,

A.V.Shpak, O.A. Shpigun " Noninvasive detection of counterfeited

ampoules of dexamethasone using NIR with confirmation by HPLC-DAD-MS and

CE-UV methods " Anal Bioanal Chem 397, 1927–1935 (2010)

DOI: 10.1007/s00216-010-3711-y |

Click

here

to ask for the file by e-mail |

There is no simple solution to the problem of

counterfeit drug detection. The so-called 'high quality fakes' with proper

composition are the most difficult to reveal. The methods based only on

quantitative determination of active ingredients are sometimes insufficient.

A more general approach is to consider a remedy as a whole object, taking

into account a complex composition of active ingredients, excipients, as

well as manufacturing conditions, such as degree of drying, etc. The

application of NIR measurements combined with chemometric data processing is

an effective method but its superficial application simplicity may lead to

wrong conclusions that undermine confidence in the technique. The main

drawback of the NIR-based approach is the necessity to apply

multivariate/chemometric data analysis in order to extract useful

information from the acquired spectra.

|

|

|

Fig. VII.5: Spectra after

pre-processing: blue (green) lines G are genuine samples, red

lines F are counterfeit samples

Left. Sildenafil. The whole spectra and the range selected by a

program

Right Metronidazole. The whole spectra and the range with high water

influence |

We've published an overview of the experience

of different research groups in NIR drug detection and highlights the main

issues that should be taken into account. The common problems to be dealt

with are the following:

(1) each medical product should be carefully tested

for a batch-to-batch variability;

(2) the selection of a specific spectral

region and the data pre-processing method should be done for each type of

medicine individually;

(3) it is crucial to recognize counterfeits as well

as to avoid misclassification of the genuine samples.

The real-world

examples presented in the paper illustrate these statements.

O.Ye. Rodionova, A.L. Pomerantsev,"NIR

based approach to counterfeit-drug detection"

Trends Anal. Chem., 29 (8),

781-938 (2010)

DOI: 10.1016/j.trac.2010.05.004 |

Click

here

to ask for the file by e-mail |

|

|

|

VIII. PAT & QbD

Process Analytical Technology

(PAT) and Quality by

Design (QbD) are the novel approaches for designing, analyzing, and controlling

manufacturing through timely measurements (i.e., during processing) of critical

quality and performance attributes of raw and in-process materials and

processes, with the goal of ensuring final product quality. Several studies in

this area have been performed in the group.

Methods of process control and optimization are

presented and illustrated with a real world example. We

considered a multi-stage technological process that is represented by 25 process

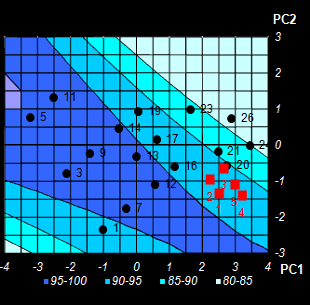

variables and one output variable, y, which is the final quality of the end-product.

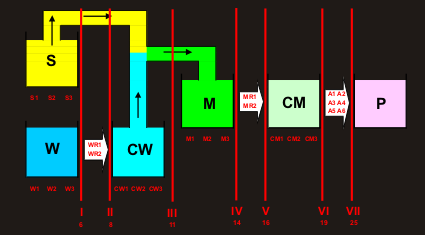

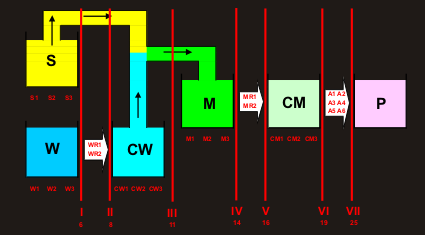

The production cycle (see

Fig.

VIII.1) is divided

into seven stages numbered by the Roman numerals. Each stage may be described by

the input, current, and further variables. Variables used in all previous stages

are fixed input variables, current variables are the controlled ones, and the

variables that characterize the following production stages are out of scope at

the moment. Moving along the process, variables change their roles.

Fig. VIII.1: Production cycle

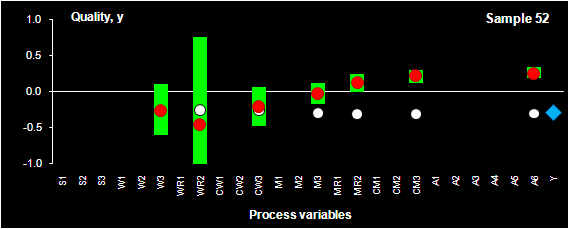

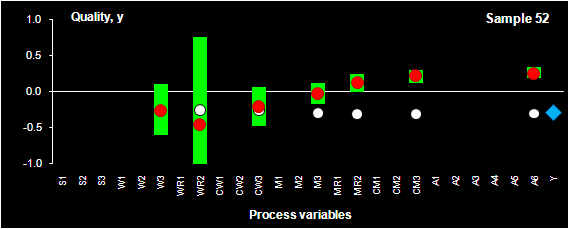

The optimization methods

are based on the PLS block modeling as well as on the Simple

Interval Calculation methods of interval prediction and object status

classification. It is proposed to employ the series of expanding PLS/SIC models

in order to support the on-line process improvements. This method helps to

predict the effect of planned actions on the product quality, and thus enables

passive quality control. We have also considered an optimization approach that

proposes the correcting actions for the quality improvement in the course of

production. The latter is an active quality optimization, which takes into

account the actual history of the process. The advocate approach is allied to

the conventional method of multivariate statistical process control (MSPC) as it

also employs the historical process data as a basis for modeling. On the other

hand, the presented concept aims more at the process optimization than at the

process control. Therefore, it is proposed to call such an approach as

multivariate statistical process optimization (MSPO).

Fig. VIII.2: Process optimization. SIC intervals (green bars), PLS prediction

(red dots) for sample 52.

Blue rhombus shows the historical quality value, y, that was actually obtained

in the production.

White dots represent the PLS predictions for the control set.

Click the icon

to open a PowerPoint file (=1MB) "Multivariate

Statistical Process Optimization ", presented at the Third Winter School on

Chemometrics (WSC-3),

PushGory , Russia, 2004

to open a PowerPoint file (=1MB) "Multivariate

Statistical Process Optimization ", presented at the Third Winter School on

Chemometrics (WSC-3),

PushGory , Russia, 2004 |

Click

here

to ask for the file by e-mail |

A.L. Pomerantsev, O.Ye. Rodionova, A. Höskuldsson,

"Process control and optimization with simple interval calculation method",

Chemom. Intell. Lab.Syst., 81 (2), 165-179 (2006)

DOI:10.1016/j.chemolab.2005.12.005 |

Click

here

to ask for the file by e-mail |

The possibility of routine testing of pharmaceutical

substances directly in warehouses is of great importance for manufactures,

especially taking into account the demands of PAT. The application of NIR

instruments with remote fiber optic probe makes these measurements simple and

rapid. On the other hand carrying out measurements through closed polyethylene

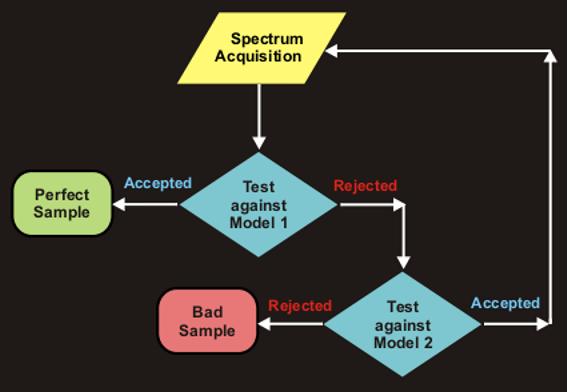

bags is a real challenge. To make the whole procedure reliable we propose the

special trichotomy classification procedure. The approach is illustrated by a

real-world example.

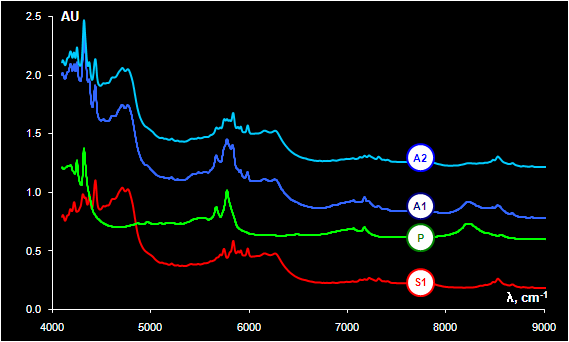

Fig. VIII.3: Spectrum S1 obtained from sample 1 without PE bag (substance), P

is a spectrum of PE bag,

A1 is a spectrum of sample 1 in PE bag, A2 is a spectrum of sample 2 in PE bag

The substance under investigation is Taurine, a

non-essential sulfur-containing amino acid. The NIR spectra were recorded with a

hand held diffuse reflectance fiber optic probe. The spectra were measured

through closed polyethylene (PE) bags in the 4000 – 10000 cm-1 region. The

explorative PCA of the dataset shows an essential difference between

the samples (Fig. VIII.3). More than 60 objects (out of 246) may be treated as doubtless

outliers. The source of such variations was found after comparing the spectra of

the substance in a bag, the spectra of unpacked substance (S1), and the spectra

of empty polyethylene bags (P).

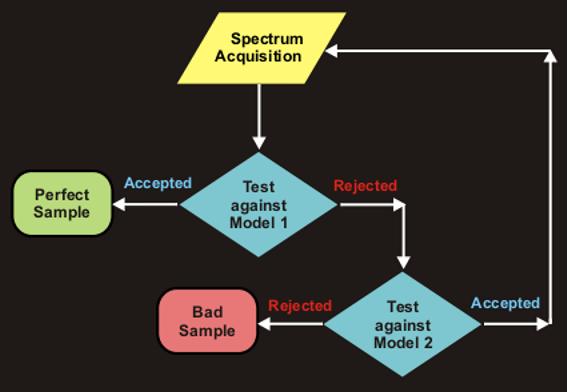

Samples that are measured successfully (through a single PE layer) belong to

Class 1. Other samples that are not measured carefully (through the several PE

layer) are attributed to Class 2. Two corresponding SIMCA models participate in

the following routine testing procedure.

- If a sample belongs to Class 1 (Model 1), this is a sample of a

satisfactory quality (decision “accepted”);

- If a sample belongs to Class 2 (Model 2), measurement should be repeated

(no decision);

- If a sample does not belong to Class 2, such a sample is an alien

(decision “rejected”).

The flowchart of the routine testing is shown in Fig. VIII.4

Fig. VIII.4: The flowchart of the sample routine testing

.Ye. Rodionova, Ya.V. Sokovikov, A.L. Pomerantsev "

Quality control of packed raw materials in pharmaceutical industry"

Anal. Chim. Acta , 642(1-2), 222-227 (2009)

DOI:

10.1016/j.aca.2008.08.004 |

Click

here

to ask for the file by e-mail |

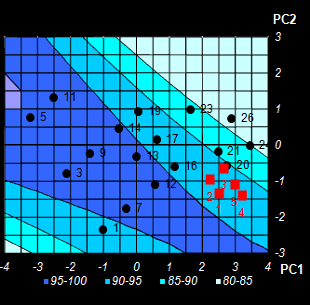

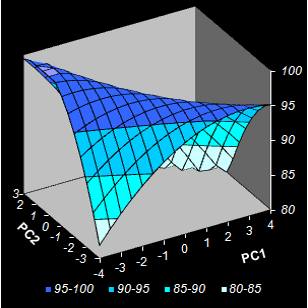

This QbD research is aimed at optimization of a hybrid binder formulation that

includes water solution of sodium silicate (water glass) and polyisocyanate.

Optimization is performed with respect to twelve output quality characteristics.

Calibration modeling is done as a two-step NPCR procedure. At first, PCA is

applied to the X- block for variable reduction. Then nonlinear regression is

used to predict a particular quality characteristic as a function of score

vectors. The input variables reduction enables to choose an optimal binder

formulation that meets the predefined quality requirements.

|

|

|

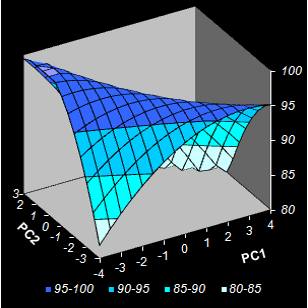

Fig. VIII.5: Conversion level predicted by NPCR.

Color intensity reflects the property value.

Contour map. Black dots are the calibration points, red squares are optimized test

points (Left);

3-D surface model (Right) . |

The study demonstrates the benefits of chemometric approach in application to

chemical engineering. The non-linear PCR solves a complex nonlinear multivariate

optimization problem employing a simple projection approach and graphical

representation of the models. The input variables' reduction gives an

opportunity to choose the optimal binder formulations visually without

complicated numerical procedures.

I.A. Starovoitova, V.G. Khozin, L.A. Abdrakhmanova,

O.Ye. Rodionova, A.L. Pomerantsev "Application of nonlinear PCR for

optimization of hybrid binder used in construction materials", Chemom.

Intell. Lab.Syst., 97 (1), 46-51 (2009)

DOI:

10.1016/j.chemolab.2008.07.008 |

Click

here

to ask for the file by e-mail |

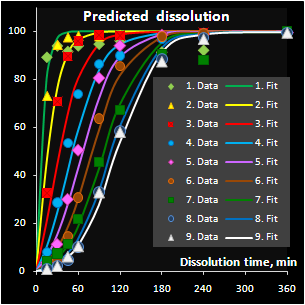

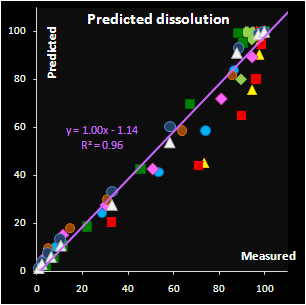

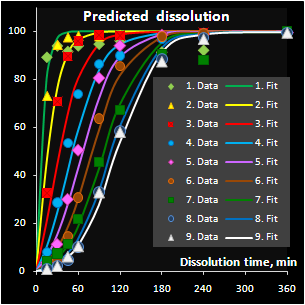

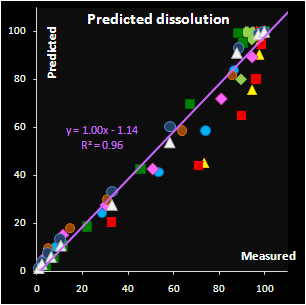

A new method for prediction of the drug release

profiles during a running pellet coating process from in-line near infrared

(NIR) measurements has been developed. The NIR spectra were acquired during a

manufacturing process through an immersion probe. These spectra reflect the

coating thickness that is inherently connected with the drug release. Pellets

sampled at nine process time points from thirteen designed laboratory-scale

coating batches were subjected to the dissolution testing. In the case of the

pH-sensitive Acryl-EZE coating the drug release kinetics for the acidic medium

has a sigmoid form with a pronounced induction period that tends to grow along

with the coating thickness. In this work the autocatalytic model adopted from

the chemical kinetics has been successfully applied to describe the drug

release. A generalized interpretation of the kinetic constants in terms of the

process and product parameters has been suggested. A combination of the kinetic

model with the multivariate Partial Least Squares (PLS) regression enabled

prediction of the release profiles from the process NIR data. The method can be

used to monitor the final pellet quality in the course of a coating process

Fig. VIII.6: Research goal

A valuable theoretical result is the solution of the

“curve-to-curve” calibration problem and in the particular case considered here,

the prediction of the drug release profiles from NIR spectra. This method

differs from the conventional approach, where a curve is restored from the

individually calibrated and predicted points. The advocated approach extracts

new features as the parameters of a function approximating the drug release

profile. Such a function can be selected on a purely empirical basis, or derived

from the fundamental process knowledge. Additionally, successful approximation

results in a considerable data reduction. The main merit however is the ability

to predict the whole curve smoothly.

|

|

|

Fig. VII.7: Predicted API release curves |

It has been found that the autocatalytic model

perfectly fits the drug release kinetics of the pellets coated by a

pH-sensitive polymer. Moreover, two underlying kinetic constants have a

reasonable physical interpretation. The first parameter, m, is

responsible for the coating material grade and this parameter varies

neither within a batch nor between the similar batches. The second

parameter, k, is closely related to the coating thickness and this

dependence is individual for every batch. Subsequently, the

autocatalysis is a mechanical rather than a purely empirical model. A

preliminary explanation of the mechanism's nature has been suggested.

Click the icon

to open presentation (=1.3 MB) "In-line prediction of drug

release profile for pH-sensitive coated pellets", 12- th

International Conference on Chemometrics in Analytical Chemistry

(CAC-2010), Antwerp, Belgium, 2010

to open presentation (=1.3 MB) "In-line prediction of drug

release profile for pH-sensitive coated pellets", 12- th

International Conference on Chemometrics in Analytical Chemistry

(CAC-2010), Antwerp, Belgium, 2010 |

Click

here

to ask for the file by e-mail |

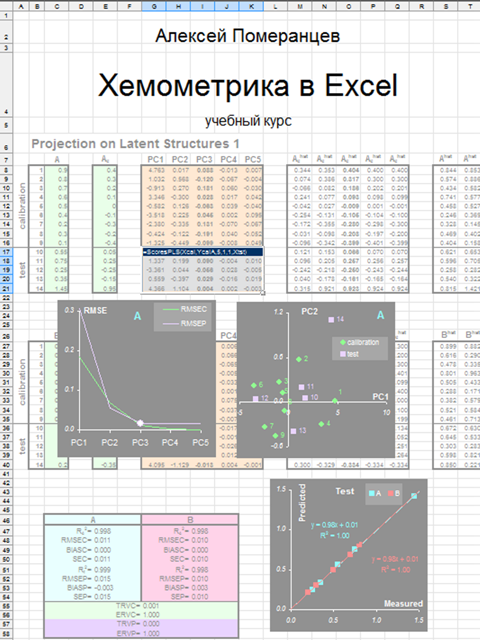

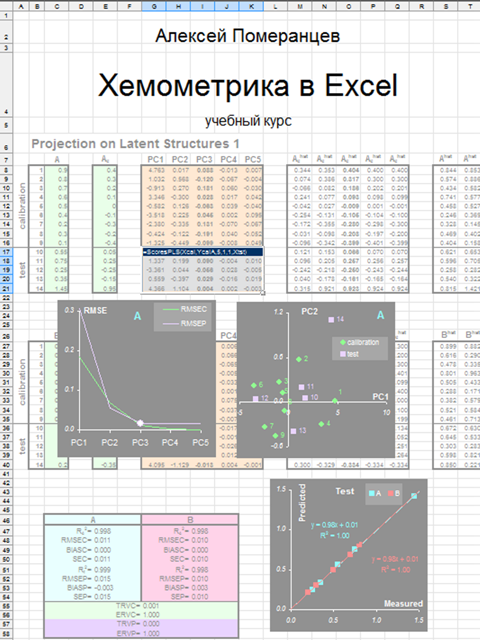

IX. Chemometrics in Excel

Chemometrics is a very practical discipline. To learn

it one should not only understand the numerous chemometric methods, but also

adopt their practical application. This book can assist you in this difficult

task. It is aimed primarily at those who are interested in the analysis of

experimental data: chemists, physicists, biologists, and others. It can also

serve as an introduction for beginners who start learning about multivariate

data analysis.

|

|

|

Fig. IX.1: Russian & English editions of the

book |

| A.L. Pomerantsev, Chemometrics in Excel, Wiley, 336

pages, 2014 , ISBN: 978-1-118-60535-6 |

Click

here

to order the book |

| Ïîìåðàíöåâ À.Ë. Õåìîìåòðèêà â Excel: ó÷åáíîå ïîñîáèå,

Òîìñê, Èç-âî ÒÏÓ, 435 ñòð.,2014, ISBN 978-5-4387-0374-7 |

|

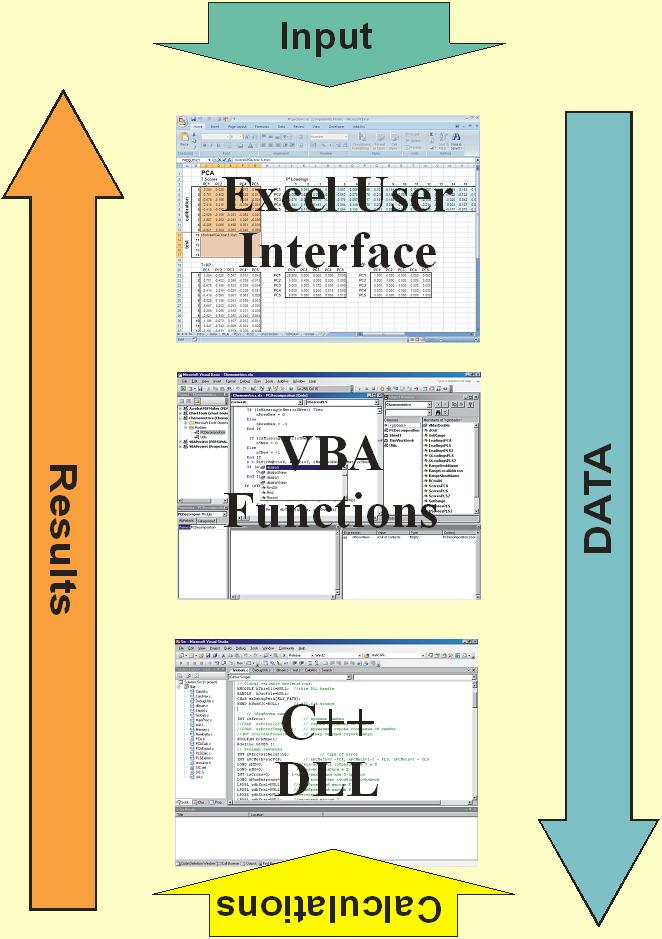

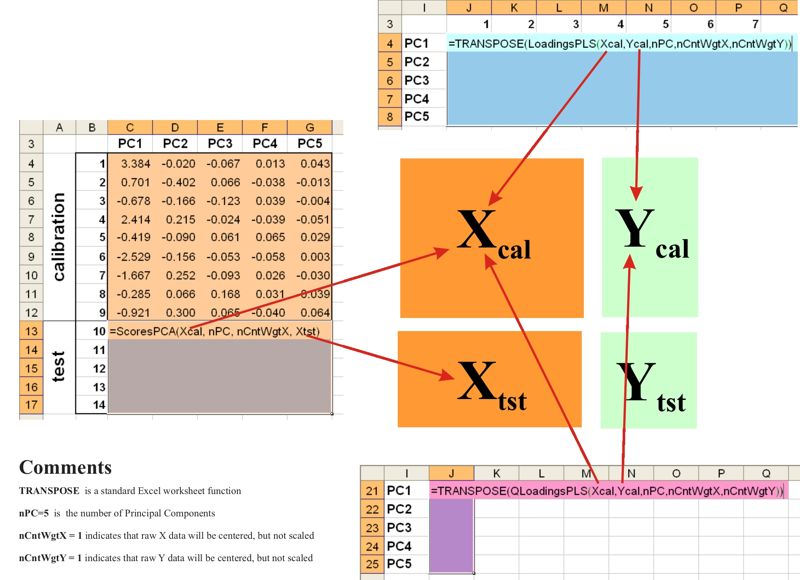

The conventional way of chemometrics training utilizes

either specialized programs (the Unscrambler, SIMCA, etc.), or the MatLab. We

suggest our own method that employs the abilities of the world’s most popular

program, Microsoft Excel®. However, the main chemometric algorithms, e.g.

projection methods (PCA, PLS) are difficult to implement using basic Excel

facilities. Therefore, we have developed a special supplement to the standard

Excel version called Chemometrics AddIn, which can be used to perform such

calculations. In this case all calculations are carried out in the open Excel

books. Moreover all regular Excel capacities can be applied for additional

calculations, graphical presentations, export and import of data and results,

customizing individual templates, etc. Excel 2007 gives additional incentive to

this idea as now very large arrays (1,048,576 rows by 16,384 columns) can be

input and processed directly in the worksheets. We have designed the core

functions for the PCA/PLS decompositions and ensured that calculations are

performed very quickly even for rather large data sets (200 samples by 4500

variables). These functions are programmed in C++ language and linked to Excel

as an Add-In tool named Chemometrics Add-in.

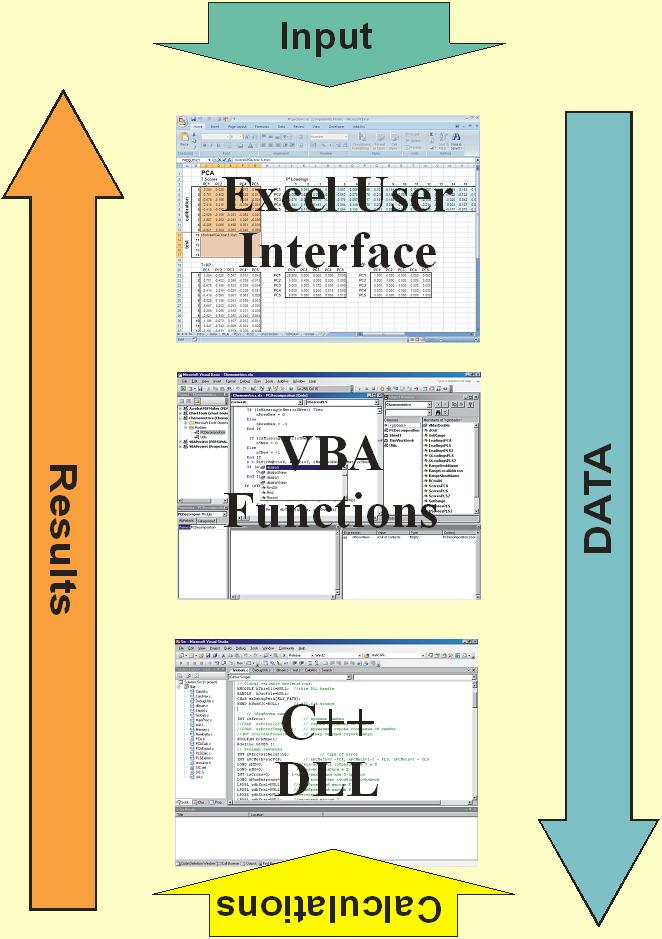

Fig IX.2: Software flow-chart

We designed "Chemometrics" as an Add-In

procedure for Excel. This add-in file is opened by a Tools/Add-Ins menu

command. After that, main projection functions can be applied as ordinary

user-defined functions in Excel.

-

All calculations are carried out in the open

Excel books.

-

All results are also output as tables on the

worksheets.

-

All calculations are made "on the

fly".

-

As soon as a user changes any cell in the

input data, output data are recalculated automatically (if

"automatic" option is switched on in a

Tools/Options/Calculation menu).

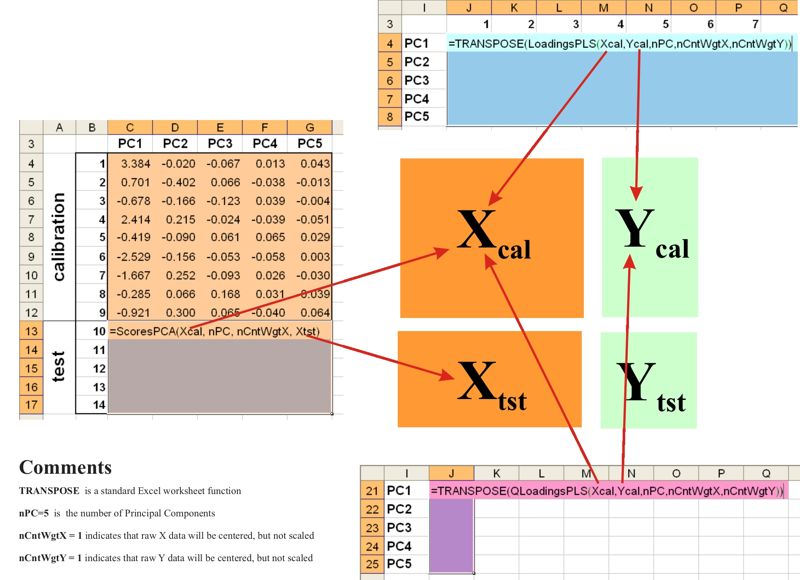

Fig IX.3: Common worksheet layout for application of Chemometrics Add-In

List of user-defined

functions

PCA Decomposition

-

ScoresPCA (X, PC, CentWeight, Xnew )

-

LoadingsPCA (X, PC, CentWeight )

PLS Decomposition

-

ScoresPLS (X, Y, PC, CentWeightX, CentWeightY

, Xnew)

-

UScoresPLS (X, Y, PC, CentWeightX, CentWeightY,

Xnew, Ynew )

-

LoadingsPLS (X, Y, PC, CentWeightX, CentWeightY )

-

WLoadingsPLS (X, Y, PC, CentWeightX, CentWeightY )

-

QLoadingsPLS (X, Y, PC, CentWeightX, CentWeightY )

PLS2 Decomposition

-

ScoresPLS2 (X, Y, PC, CentWeightX, CentWeightY

, Xnew)

-

UScoresPLS2 (X, Y, PC, CentWeightX, CentWeightY,

Xnew, Ynew )

-

LoadingsPLS2 (X, Y, PC, CentWeightX, CentWeightY )

-

WLoadingsPLS2 (X, Y, PC, CentWeightX, CentWeightY )

-

QLoadingsPLS2 (X, Y, PC, CentWeightX, CentWeightY )

Click the icon

to open a PowerPoint file (=2335 kB) "Chemometric functions in Excel", presented at

the First

Symposium of South African Chemometrics Society (Stellenbosch

University, South Africa).

to open a PowerPoint file (=2335 kB) "Chemometric functions in Excel", presented at

the First

Symposium of South African Chemometrics Society (Stellenbosch

University, South Africa). |

Click

here

to ask for the file by e-mail |

Click

here

to

know more about Chemometrics Add-In.

|

|

|

Last update

06.11.19

![]() )

are the calibration objects.

)

are the calibration objects. ![]() ) are

the test objects.

) are

the test objects.